Skyjet Polymer offers premium PTFE, a high-performance fluoropolymer renowned for its exceptional properties. PTFE boasts unparalleled chemical resistance, withstanding aggressive acids, bases, and solvents, making it ideal for harsh industrial environments. Its low coefficient of friction ensures excellent non-stick properties, reducing wear and enhancing efficiency in applications like seals, gaskets, and linings. With a wide operating temperature range of -200°C to +260°C, PTFE maintains stability in extreme conditions. Additionally, its superior electrical insulation properties and resistance to UV radiation and weathering make it a top choice for critical applications in chemical processing, electronics, and aerospace industries. Skyjet Polymer’s PTFE solutions are customizable, ensuring durability, reliability, and cost-effectiveness for your specific needs.

Skyjet Polymer specializes in UHMWPE, a versatile thermoplastic known for its outstanding toughness and performance. UHMWPE offers exceptional abrasion resistance, surpassing most plastics, making it ideal for wear-resistant components in industries like mining, material handling, and food processing. Its high impact strength ensures durability even under heavy mechanical stress, while its low friction coefficient supports smooth operation in applications like conveyor systems and liners. UHMWPE is also highly resistant to chemicals, moisture, and UV exposure, ensuring long-term reliability in harsh environments. With excellent low-temperature performance and FDA compliance for food contact, Skyjet Polymer’s customizable UHMWPE solutions deliver cost-effective, high-quality performance tailored to demanding industrial applications.

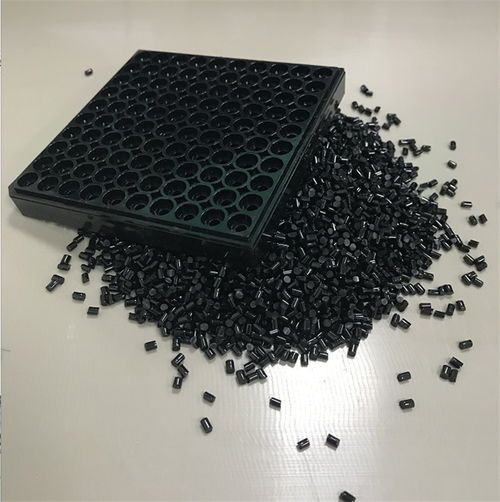

Skyjet Polymer provides high-performance PEEK, a semi-crystalline thermoplastic celebrated for its superior mechanical and chemical properties. PEEK offers exceptional strength and stiffness, maintaining structural integrity under high temperatures up to 250°C. Its excellent chemical resistance makes it suitable for aggressive environments, resisting acids, oils, and solvents. PEEK’s low moisture absorption and high wear resistance ensure reliability in demanding applications such as aerospace components, medical devices, and automotive parts. Additionally, its inherent flame retardancy and low smoke emission enhance safety in critical settings. Skyjet Polymer’s customizable PEEK solutions combine precision engineering with cost-effectiveness, delivering durable, high-quality components that meet the rigorous demands of advanced industrial applications.