Skyjet Polymer

Your Partner For Advanced Polymer Solutions

- 32 years of experience in mechanical design and mold manufacturing

- Advanced ram extrusion technology

- A top-tier R&D team and an unwavering spirit of research and development.

Hot Products

We collaborate with top polymer laboratory in China to jointly develop the latest PTFE, UHMWPE, and PEEK solutions.

Our Manufacturing Capabilities

After 15 years of development, Skyjet Polymer has a wealth of processing and manufacturing technologies for polymer materials. From the research and development of raw material formulas to advanced extrusion methods and finished product processing, we can provide customers with satisfactory services.

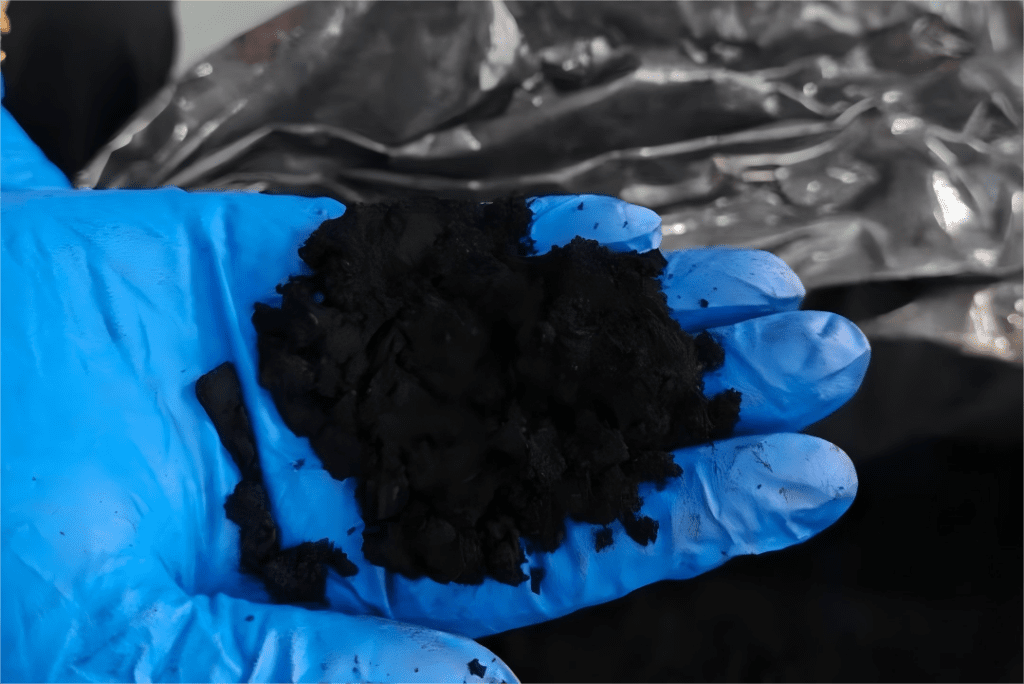

Formula Development

We cooperate with the top domestic polymer material modification laboratories and can provide modified formulas for PTFE, UHMWPE and PEEK

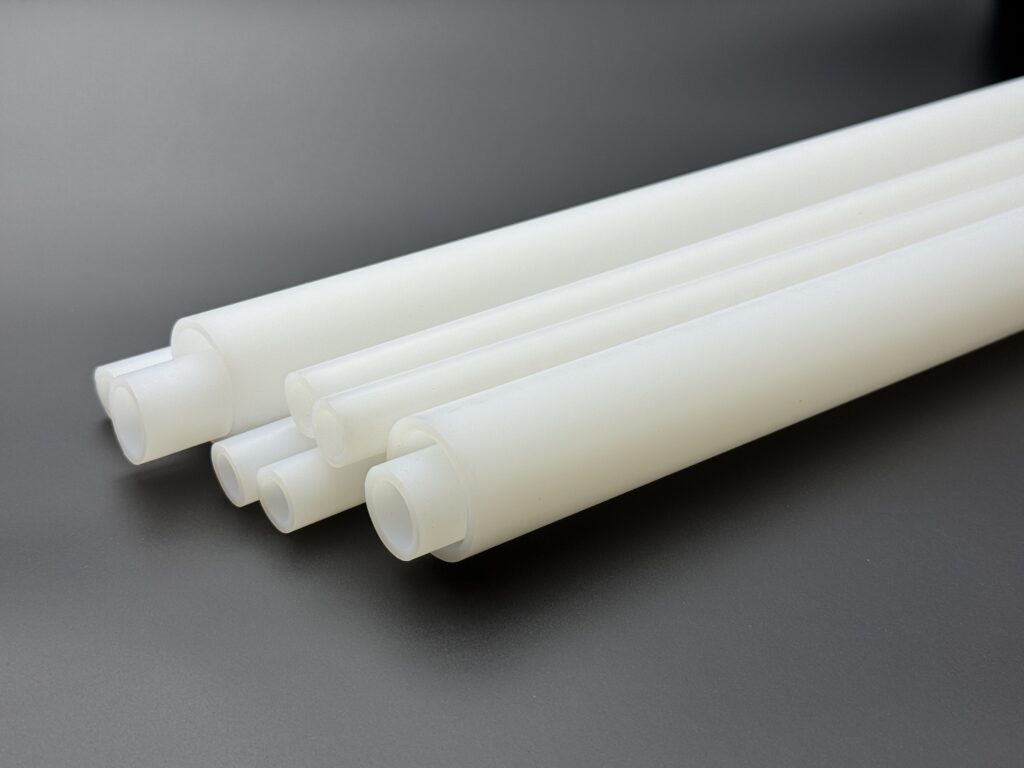

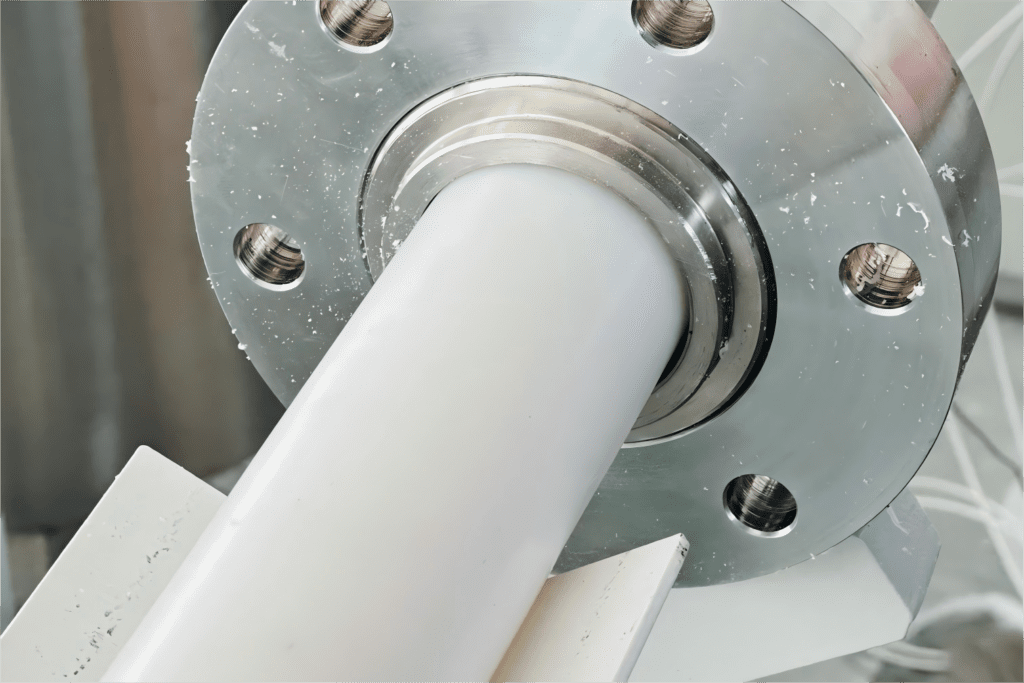

Extrusion

Our vertical and horizontal ram extruders guarantee product density and performance.

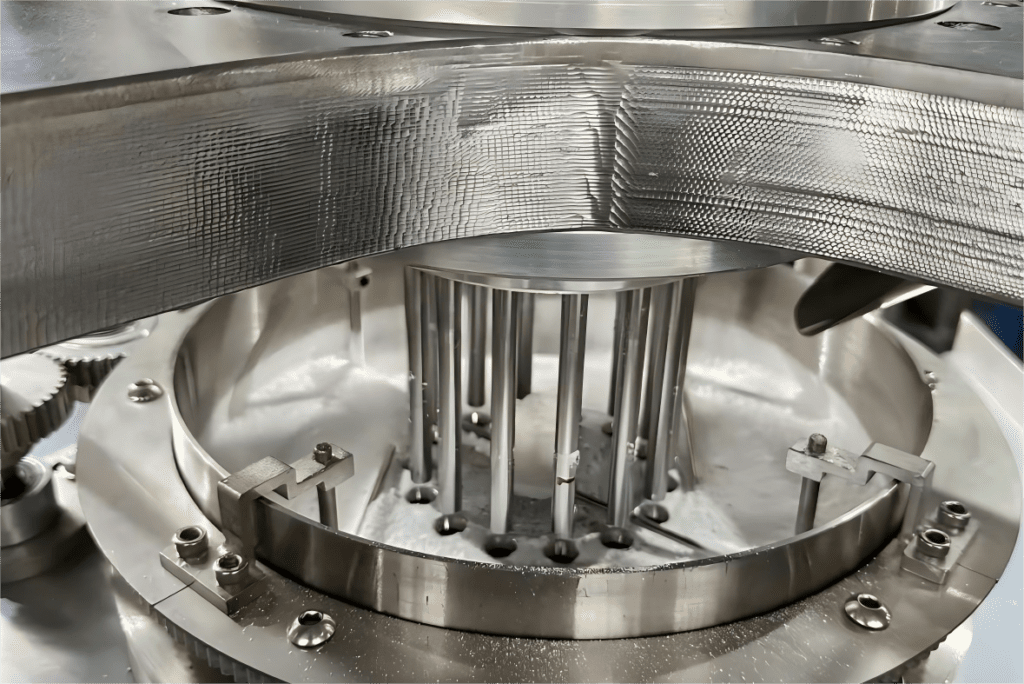

Molding & Sintering

We have over 20 years of experience in PTFE molding and sintering, and can fully grasp the density and performance of the product. We can also provide UHMWPE hot-pressed products.

Polymer Mold Development

Our engineers have 15 years of experience in polymer material mold design and processing. We can customize materials and processes for molds made of different materials.

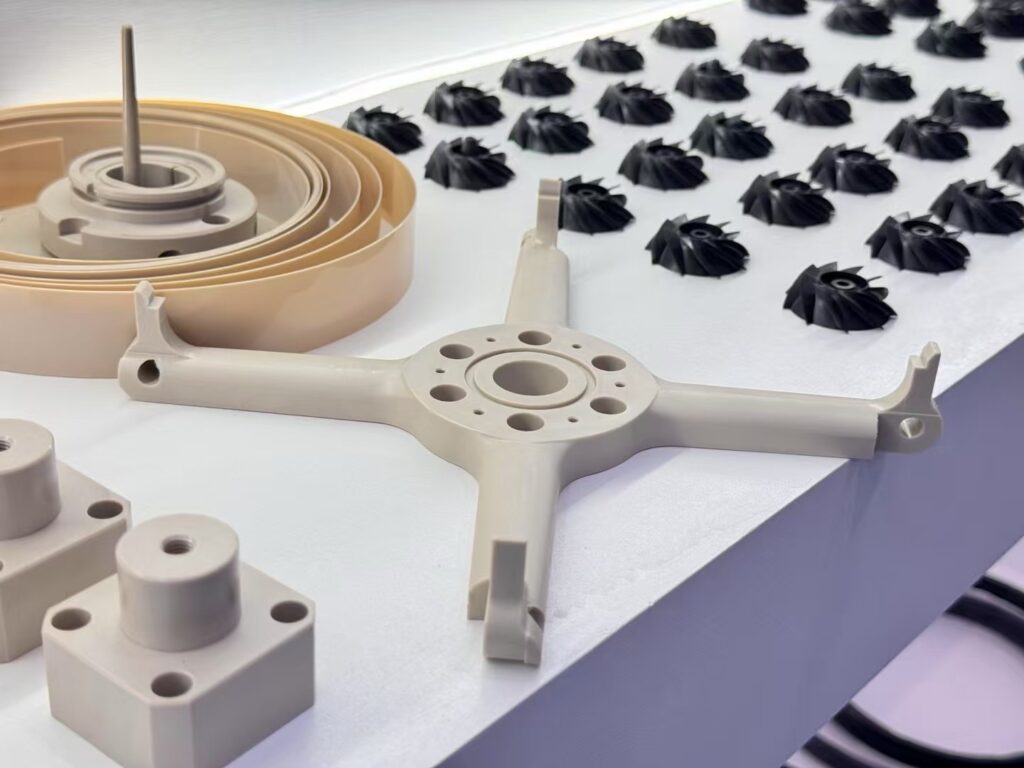

CNC Machining

We have more than 20 precision processing equipment, including five-axis CNC, four-axis CNC and high-precision lathes to ensure the accuracy of the products.

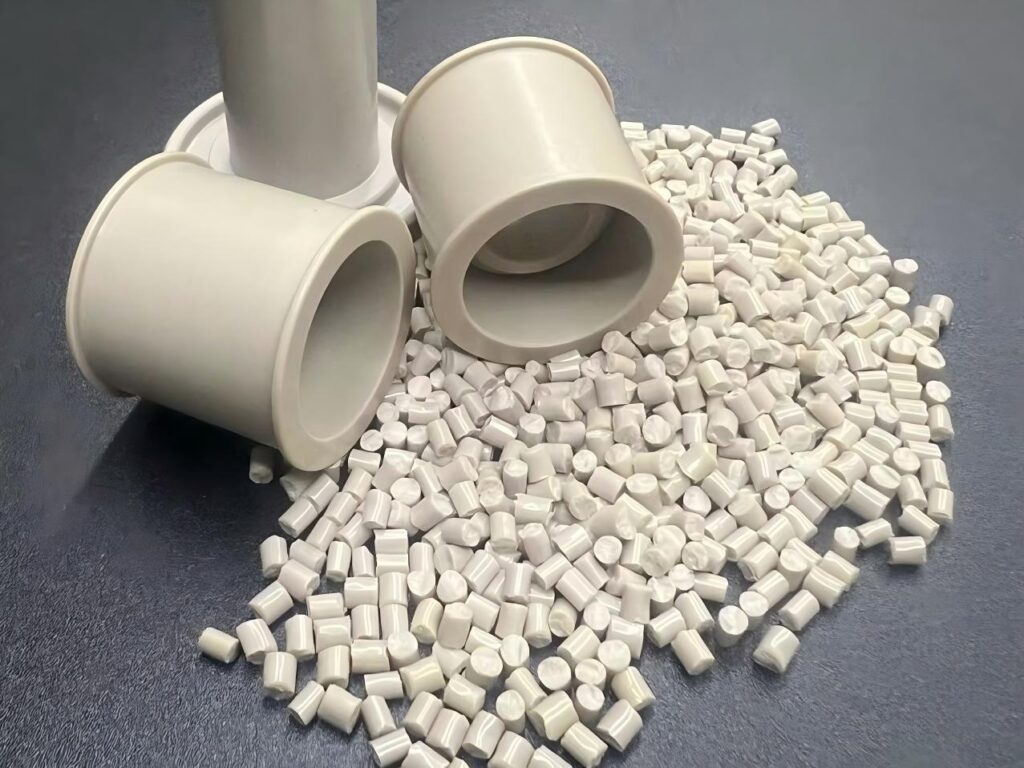

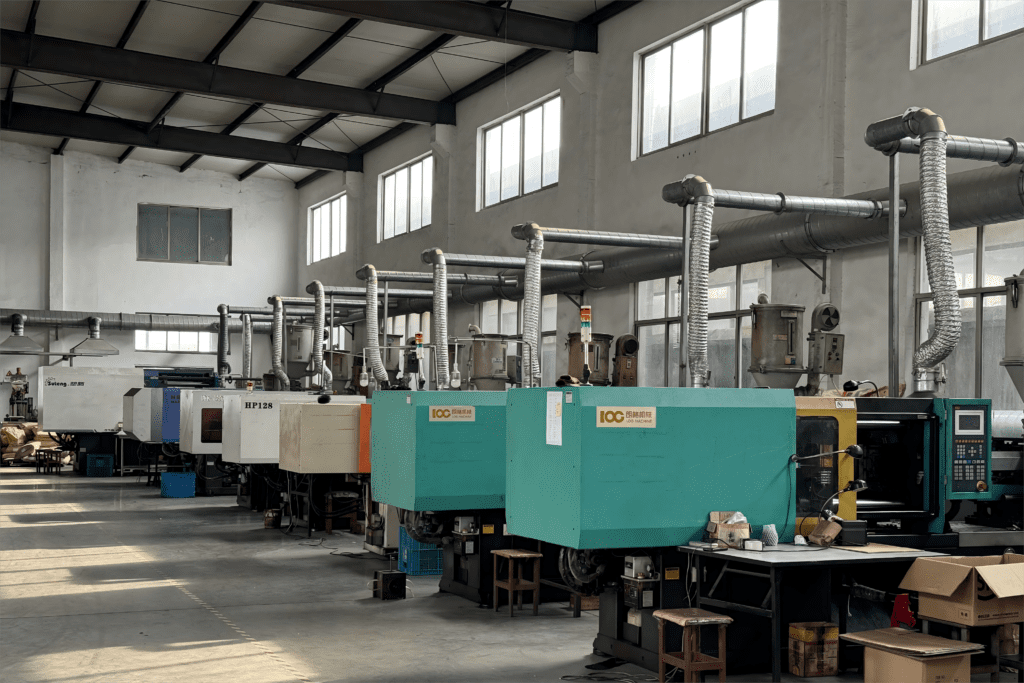

Injection Molding

Our injection molding workshop was established 15 years ago and has two process engineers with 30 years of experience. We can handle a variety of melt extrusion materials with ease.

Industries We Serve

Our high-performance plastics serve diverse industries, including aerospace, medical, automotive, water treatment, fluid hydraulics, sealing, and petroleum. We specialize in materials like PTFE, UHMWPE, and PEEK, chosen for their exceptional properties that meet demanding applications.

PTFE offers unmatched chemical resistance, low friction, and high-temperature stability, making it ideal for seals and gaskets in aerospace and petroleum.

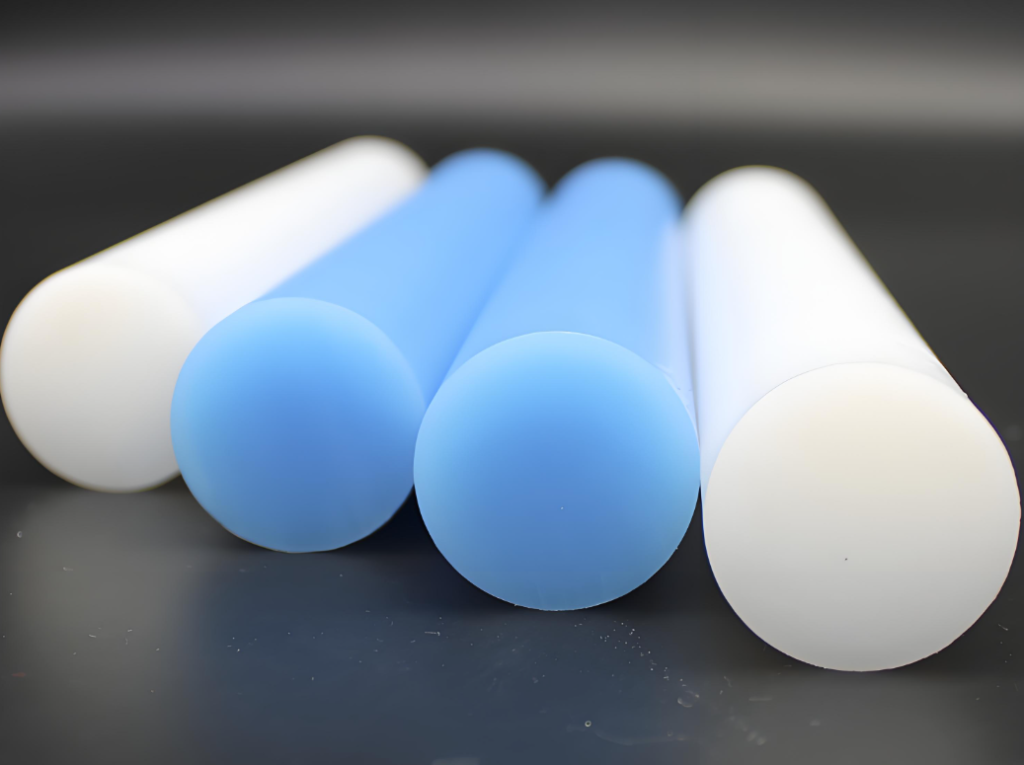

UHMWPE provides superior wear resistance, impact strength, and biocompatibility, perfect for medical implants and water treatment components.

PEEK excels in high-strength, heat-resistant applications, ensuring durability in automotive and hydraulic systems. These materials deliver reliability, longevity, and efficiency, enabling innovative solutions across industries. Partner with us to leverage their advanced performance for your next project.

Blogs & News

As data centers evolve to handle the demands of AI, cloud computing, and high-performance computing, liquid cooling systems have become essential for efficient heat dissipation.

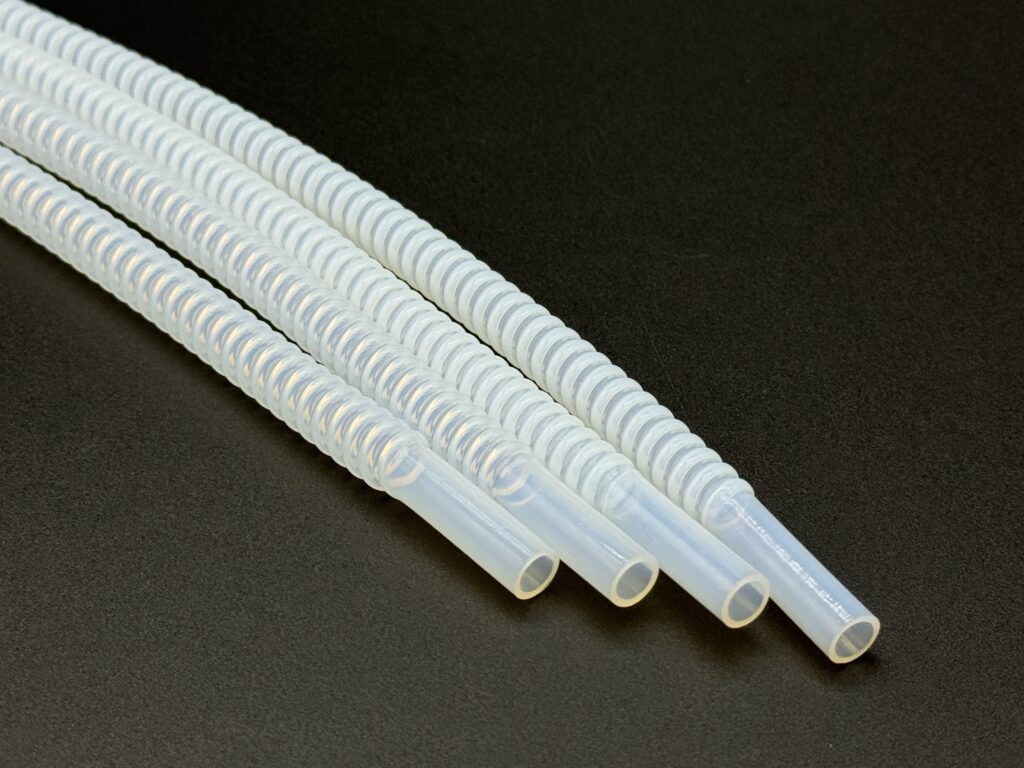

PTFE corrugated hoses are basically made by taking a straight PTFE tube, heating it up, and blow-molding it under pressure to form those classic convolutions.

Written by Alex Zhang Technical Director at Skyjet Polymer – 18 years doing nothing but high-performance plastics Last month alone we had 42 incoming calls

When customers search for UHMWPE rod, UHMWPE sheet, or UHMWPE tube, one of the most frequently asked questions is: “Should I choose ram extruded UHMW-PE